|

The first telephonic repeaters were

of electromechanical type and in this way insufficient to

follow the increasing expansion of the telephonic lines.

The engineers had soon noticed they needed a new type of telephonic

repeater that besides acting as

|

| Irwing Langmuir |

signal amplifier, it should have

also several technical operational and commercial capabilities

such as: - to amplify all the frequency range without distorsion;

durability and quick interchangeability with similar devices,

as well as low manufacturing cost.

However, around 1910, the triode valve was still a simple

thermionic device and in this way, it did not have the necessary

conditions to meet such requirements.

Around 1916, the valve had already suffered enormous technological

modifications either on its structural as well as its operational

concepts. Amongst its main technological advances are:

-Filament or heater: the first type, was the one coated by

oxides whose technique was invented by Wehnelt. Soon followed

the tungsten-thoriated filament, an alloy made of tungsten

and thorium. (a) However, those new types of filaments demanded

the operation in low oxygen atmosphere for the proper electron

emission.

The gettering technique: this deficiency was overcame by the

vaporization or the burnning inside of the glass bulb of active

chemical substances such as magnesium during the final process

of evacuation of the air in such away to remove the small

particles of atmospheric air.

The Getter could still continue active during all the life

of the valve, absorbing small amounts of emitted gaseous particles

from the structural elements of the valve, or even due to

an incompleted rarefaction. (b)

-The structural elements: the first valves used as telephone

repeaters were substantially improved by eliminating its operational

fragility. New materials were used in the manufacturing processes;

this included the base as well as for the valve inner elements

originating an asembling technique as known as Iron Clad.

Through the same the inners, elements were perfectly lined

up and finally mounted inside a glass bulb. (c) -

-The glass bulb: as aforementioned the technology of the valve

manufacturing had its origin in the electric lamp. (d) In

the first valves, the air was removed through superior part

of the bulb and then sealed by a small tip in a pearl shape.

(e) Due to the improvement in the rarefaction processs the

bulb suffered several modifications in its original shape

as well as new type of glasses were used in its manufacturing.

Among them were the lead -carbonates, and the borosilicates

glasses.

In this way, instead of using the primitive blowing process,

the bulb now was moulded in machines or lathes improving the

glass wall thickness. Around 1928 the bulb shapes were already

standardized.

During the First World War, 1914 - 1918, all the operational

conditions of the valve were already known due to the experience

acquired in the manufacturing of the ones used for telephony

applications. Such improvements certainly were extended to

those destined for equipments used for military applications.

Hence the military communication equipments should be built

considering size, rigidity as well as operating in adverse

enviroment conditions, ranging from a freezing radio tent

in the Artic, to a hot destroyer warroom in a in the tropic,

the technological evolution of the thermionics led to the

development of new and reliable types devices such as the

metal valve.

|

| a) Power triode made in the USA

using filament coated with Oxides. |

|

|

| (b) The valve type 201, with porcelain

base showing the mirrored bulb due to the gettering

processs; |

|

|

|

| (e) In the left: valve type 201

with brass base showing the glass bulb where on

its top the air was removed; in the right: same

valve but with a spherical mirrored bulb due to

the gettering. |

|

|

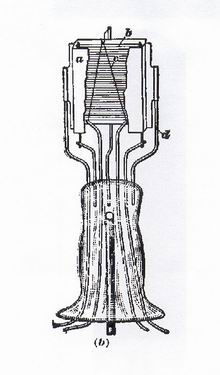

(c) Early method of assembling the structural elements

where:

A) plate

b) grid

c) filament

|

|