|

| Fig. 302 - The breedboard assembling. |

The first factory made receivers was built using the breedboard

approach. Therefore, soon due to the evolution of electrical

components as the resistors, capacitors, transformers, loudspeakers

and the thermionic valve, the breedboard

|

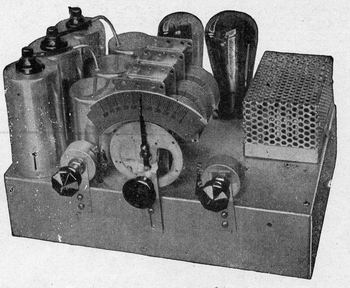

| Fig. 303 - A typical electro-mechanical

assembling showing the allocation of the tunining scale

or dial. |

technique was replaced by the metal chassis that improved so

much the receiver’s components electro-mechanical assembling.

Originally the metal chassis was made employing several mechanical

processes, such as: stamping, punching, bending and soldering;

finally, for aesthetic and protection purposes, it was coated

with an electroplated zinc layer. Fig 302

Essentially the chassis design should be mechanically and

electrically practical in such away to improve the receiver

operation. In this way,

|

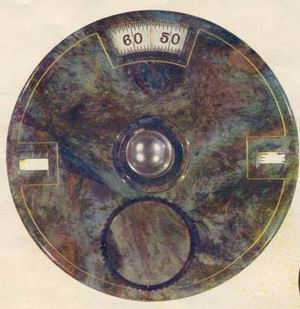

| Fig. 303A - An early type of dial or

tuning scale. |

the tunning scale or dial should be allocated for an easy reading.

Due to circuit innovation the tunning scale was provided with

the first mechanically operated tunning indicators, later replaced

by the

|

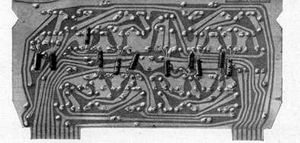

| Fig. 304 - The transistor era brought

a new technique in the electro-mechanical assembling –

the printed circuit board. |

well-known magic eye, requiring more functional and rationalized

design. Fig. 303

Yet, the receiver’s control ergonomy was deeply related

with the cabintet design for an easy operation through the

use of proper knobs.

In the early 1950’ transistor started a revolution in

the electro-mechanical assembling due to the miniaturization

of components as well as the introduction of the printed circuit

technique. Fig. 304

Therefore the aforeseen innovations gave birth to a new family

of materials, since then a perenial research task in the electronic

industry. Fig 305

|

| Fig. 305 - The on line radio receiver

electro-mechanical assembling. |

|

|